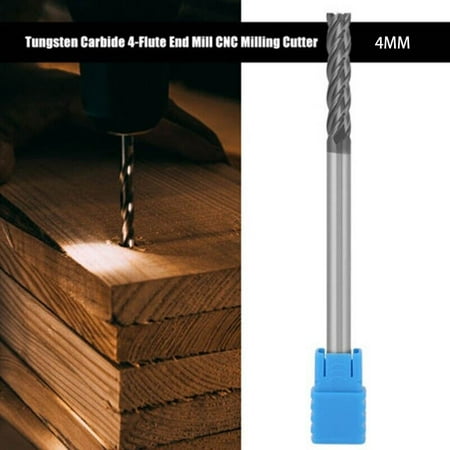

CNC Milling Cutter Milling Accessories Slotting End Mill For Milling Of Chipboard And Other Plates For Hard And Soft Solid Wood For Multilayer Board

sku: 1348604710

ACCORDING TO OUR RECORDS THIS PRODUCT IS NOT AVAILABLE NOW

$13.91

Shipping from: United States

Description

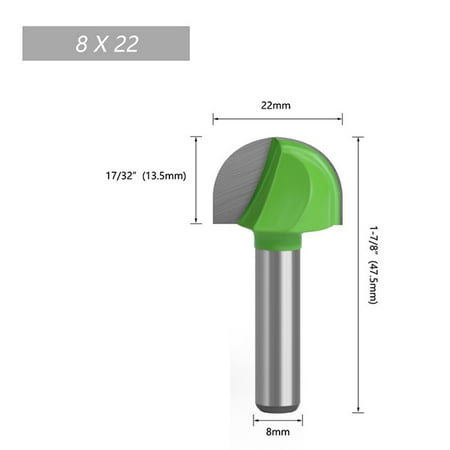

CNC Milling Cutter Milling Accessories Slotting End Mill for Milling Of Chipboard and Other Plates for Hard and Soft Solid Wood for Multilayer Board Specification: Item Type: CNC Milling Cutter Material: Carbide Model: AK47-1/2x8x20-3T Total Length: Approx. 70mm / 2.8in Shank Diameter: Approx. 12.7mm / 0.5in Blade Length: Approx. 20mm / 0.8in Blade Diameter: Approx. 8mm / 0.3in Effective Cutting Edge Number: 3 Applicable Board: Soft and hard solid wood density board multi-layer board particle board Applicable Equipment: Trimming machine electric wood milling machine hanging router CNC cutting machine only applicable to 1/2in tool holder Package List: 1 x CNC Milling Cutter Note: 1. Check the power and stiffness of the machine tool to ensure that the required milling cutter diameter can be used on the machine tool. 2. The overhang of the tool on the spindle is as short as possible to reduce the impact of the milling cutter axes and the position of the workpiece on the impact load. 3. Use the correct tooth pitch of the milling cutter suitable for the process to ensure that there are not too many blades that mesh with the workpiece at the same time and cause vibration during cutting. On the other hand ensure that there is enough when milling narrow workpieces or milling cavities. The blade engages with the workpiece. 4. Make sure to use the feed per blade so that the correct cutting effect can be obtained when the chip is thick enough to reduce tool wear. The indexable insert with positive rake angle shape is adopted to obtain a cutting effect and the lowest power. 5. Select the diameter of the milling cutter suitable for the width of the workpiece. 6. Choose the correct entering angle. 7. Place the milling cutter correctly. 9. Follow the rules of tool maintenance and repair and monitor tool wear.

Price history chart & currency exchange rate