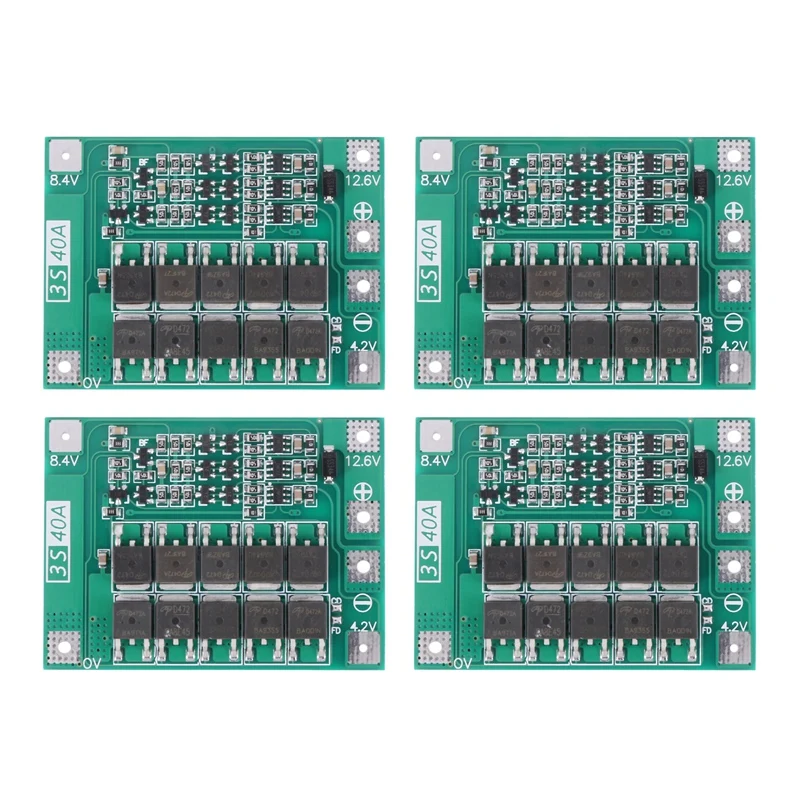

3S 40A Li-ion Lithium Battery Charger Cell Module PCB BMS Protection Board, 501 Original

Description

Descriptions:Scope of application: For lithium batteries with nominal voltage of 3.7V and full voltage of 4.2V, including 18650, 26650 and polymer lithium batteries.Product Size: 41*55*3.4mm/1.61*2.17*0.13\\\" (Enhanced Edition)Product Weight: 14g (Enhanced Edition)Charging Voltage: 12.6V-13.6VContinuous discharge current (upper limit): 40A (if the heat dissipation environment is not good, please reduce the use of load current)Continuous charging current (upper limit): 20AIt is suitable for electric drills with starting current below 80A and power below 170W.Specifications:Electrical parametersItems Minimum Typical Maximum Unit RemarksConsumption current 12 18 24 uAOvercharge protection voltage 4.2 4.25 4.3 VOvercharge recovery voltage 4.1 4.15 4.2 VOver-discharge protection voltage 2.4 2.5 2.6 VReturn Voltage 2.8 3 3.2 V 1C Discharge after Over-discharge Protection 3.2 3.5 3.8 V 2C DischargeOver-discharge recovery voltage 2.9 3.2 3.3 VOn-resistance 2.5 3 3.5 mΩOvercurrent protection current 70 80 90 AOvercurrent delay time 100 150 200 MsResistive Load with Continuous Working Current 0 40 40 AContinuous output power 0 504 504 W resistive loadAmbient temperature - 40 25 85 ℃ Common faults and treatment methods:Fault Phenomenon Fault Check and Reason Handling MethodIt is impossible to measure the voltage of three batteries by charging. If the voltage of one batteries exceeds 4.25V or so, the protection board will start over-charging protection. Match the batteries well, and don\\'t mix the good batteries with the bad ones.It is impossible to measure the voltage of three batteries by discharging. If the voltage of one batteries exceeds 2.7V or so, the protection board will start over-discharge protection.Charge/discharge failure 0V, 4.2V, 8.4V, 12.6V staggered wiring re-wiring or replacement of new boardOvercharge/Overdischarge FailureDischarge protection checks whether the battery pack is strong enough to discharge and whether the starting current of the load exceeds the overcurrent protection current of the protective plate. Replacement of batteries with stronger discharge capability or protective panels with larger currentRepair welding between one foot of virtual welding element and PCB padShort-circuit connection between two or more pins of component continuous welding element. Reweld componentWhen the electrostatic breakdown A is not electrified, the G, D and S poles of the MOS transistor are measured. If the forward and reverse resistance of any two pins are 0Ω, the breakdown is indicated. Remove and replace MOS tubeThe resistances of G and D poles, G poles and S poles of MOS transistors are measured. If there is a resistance indicating that the breakdown has occurred, the normal resistance should be infinite.Matters needing attention:1. Successful start-up of the electric drill requires three 10C-20C power batteries, or six 6C-10C power batteries, 0 V and 12.6V connection lines, using copper wires of more than 3 square millimeters (nickel sheets can not be used!!).2. Strictly follow the drawing wiring, welding line can not touch any components on the board, do not short circuit.3. When a single battery exceeds 4.2V for the first time or is being charged, the 430 resistance will generate heat and discharge (the discharge will stop at about 4.19V). If the \\\"430\\\" resistance heats up seriously, please check whether the wrong connection is made.Notes:1. Due to the different monitor and light effect, the actual color of the item might be slightly different from the color showed on the pictures. Thank you!2. Please allow 1-3cm measuring deviation due to manual measurement.Package Content:1 X Lithium Battery Protection Board

Price history chart & currency exchange rate

Customers also viewed

65%

$3.04

2 Pcs 3S Li-Ion Lithium Battery Charger Protection Board PCB BMS Protection Board 12.6V Lipo Cell Module, 20A & 40A

aliexpress.com

63%

$7.20

6X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

60%

$4.54

4X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

57%

$3.36

RISE-2X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

54%

$4.68

3X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

52%

$7.76

4X 3S 40A Li-Ion Lithium Battery Charger Protection Board PCB BMS For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

50%

$13.21

10X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

47%

$9.19

6X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

45%

$5.67

5X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

42%

$7.48

4X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms for Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

39%

$7.37

4X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

36%

$8.12

5X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

35%

$4.74

RISE-3X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

34%

$3.64

RISE-2X 3S 40A Li-Ion Lithium Battery Charger Protection Board PCB BMS For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

+1%

33%

$4.31

4X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

31%

$6.16

5X 3S 40A 18650 Li-Ion Lithium Battery Charger Protection Board Pcb Bms For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

28%

$7.56

4X 3S 40A Li-Ion Lithium Battery Charger Protection Board PCB BMS For Drill Motor 11.1V 12.6V Lipo Cell Module

aliexpress.com

-30%

23%

$5.71

6PCS 3S 40A Li-Ion Lithium Battery Charger Lipo Module PCB BMS Protection Board for Drill Motor 12.6V with Balance

aliexpress.com

20%

$4.00

3S 4S 40A Li-ion Lithium Battery 18650 Charger PCB BMS Protection Board with Balance For Drill Motor 14.8V 16.8V Lipo Module

aliexpress.com

-36%

16%

$5.56

6PCS 3S 40A Li-Ion Lithium Battery Charger Lipo Module PCB BMS Protection Board for Drill Motor 12.6V with Balance

aliexpress.com

1%

$2.73

RISE-4S 40A Li-Ion Lithium Battery 18650 Charger Pcb Bms Protection Board & 3S 20A

aliexpress.com

-19%

1%

$4.99

BMS 3S 40A 18650 Lithium Battery Charger Protection Board 11.1V 12.6V PCB for Drill Motor with Balance

banggood.com

+1%

1%

$2.90

3S 40A 12.6V 18650 Lithium Battery PCB BMS Charger Protection Board Balanced Version Auto Recovery For Drill Motor

aliexpress.com

1%

$2.28

C63B 3S 40A Зарядное устройство для литий-ионных аккумуляторов Lipo Cell Module PCB BMS для платы защиты с балансом для

aliexpress.com

1%

$10.12

10X 3S 40A 18650 Защитная плата Pcb Bms зарядного устройства для литий-ионного аккумулятора для двигателя перфоратора 11,1 В 12,6 в модуль литий-полимерной батареи

aliexpress.com

1%

$0.98

Transparent Acrylic Case Shell Box For LCR-T4 Transistor Tester Diode Triode Capacitance ESR Meter MOS PNP

aliexpress.com

+15%

1%

$363.00

Светодиодная лампа полного спектра для выращивания растений, 1000 Вт, 85-265 в

aliexpress.ru

1%

$1.19

1 Sheet Christmas Decorations Window Glass Sticker Snowflake Wall Doll Stickers Kids Room Xmas New Year Event Decor

aliexpress.com

1%

$5.19

100% натуральный шелковый шарф, женский квадратный цветочный роскошный брендовый шейный платок, шали, шарфы, Женский хиджаб, бандана

aliexpress.ru