Keencut SteelTrak 98" Vertical Substrate Cutter

Keencut SteelTraK has been designed and built by Keencut engineers to enable sign makers to easily meet the challenge of processing increasingly complex materials used in the modern sign industry. Cutting without noise or airborne debris the SteelTraK can be installed at any point in the production process without compromising valuable artwork or equipment.

Building on the huge success of the all-purpose Keencut Excalibur and recognizing the increasing demands of thicker, tougher sign materials, the SteelTraK is strong, versatile, safe and easy to use. Virtually maintenance free and built to last almost indefinitely in the toughest working conditions the SteelTraK is now a piece of essential equipment in sign making workshops in over 70 countries world-wide.

The SteelTraK 250. With an impressive cutting capacity of 250cm (8ft) operators can cut full-sized panels with ease and with three model sizes 165cm, 210cm and 250cm (65", 82" and 96") there is now a SteelTraK to suit almost every signmaking operation.

Turn & Lock Ready Mounted Tools

• Ready mounted for instant action

• Accepts standard utility blades for general purpose cutting

All Blades Cut On Same Line

• One stop setting - One measurement - One cutline cursor - No special operator training - No laser shake - Less fatigue - No wasted panels - No mistakes

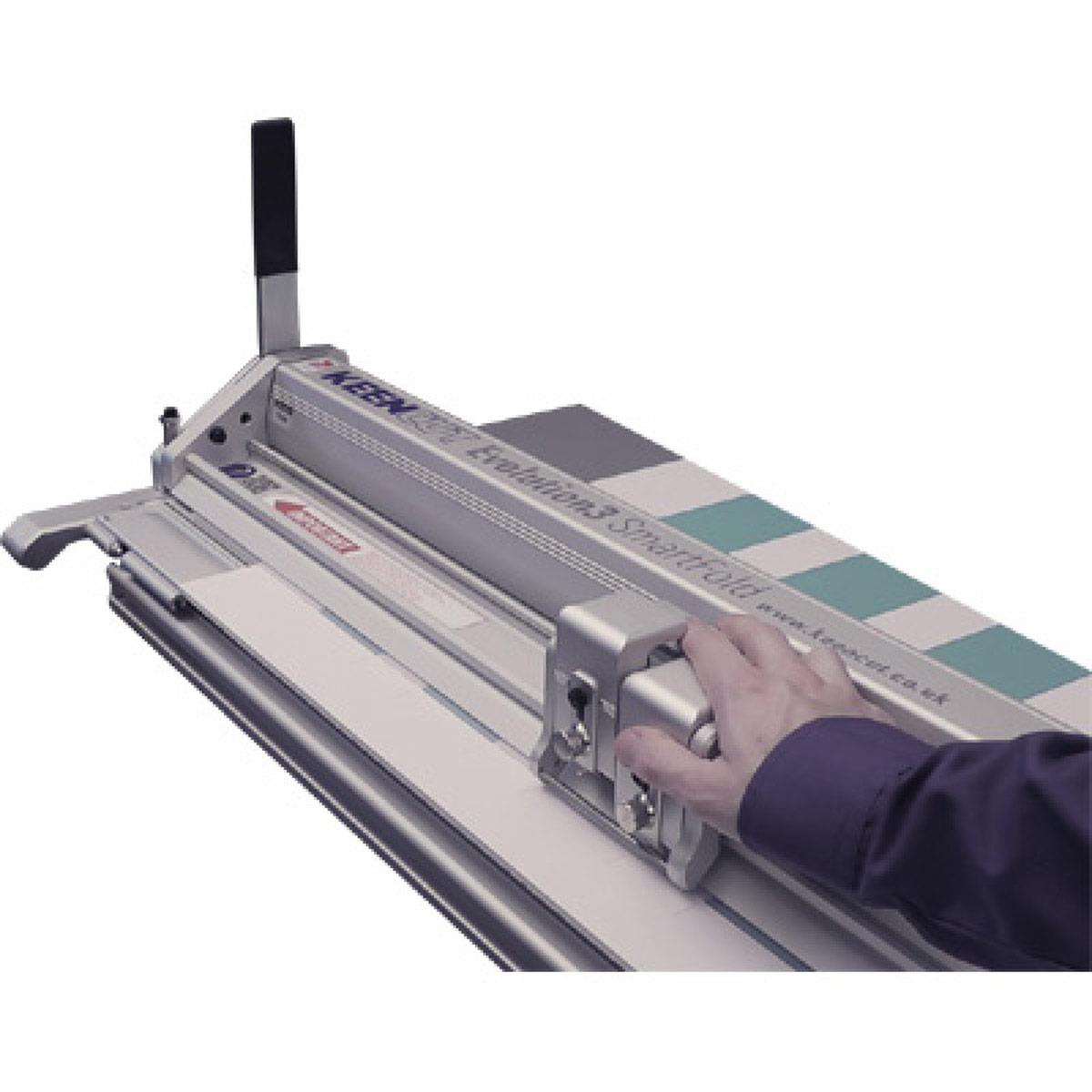

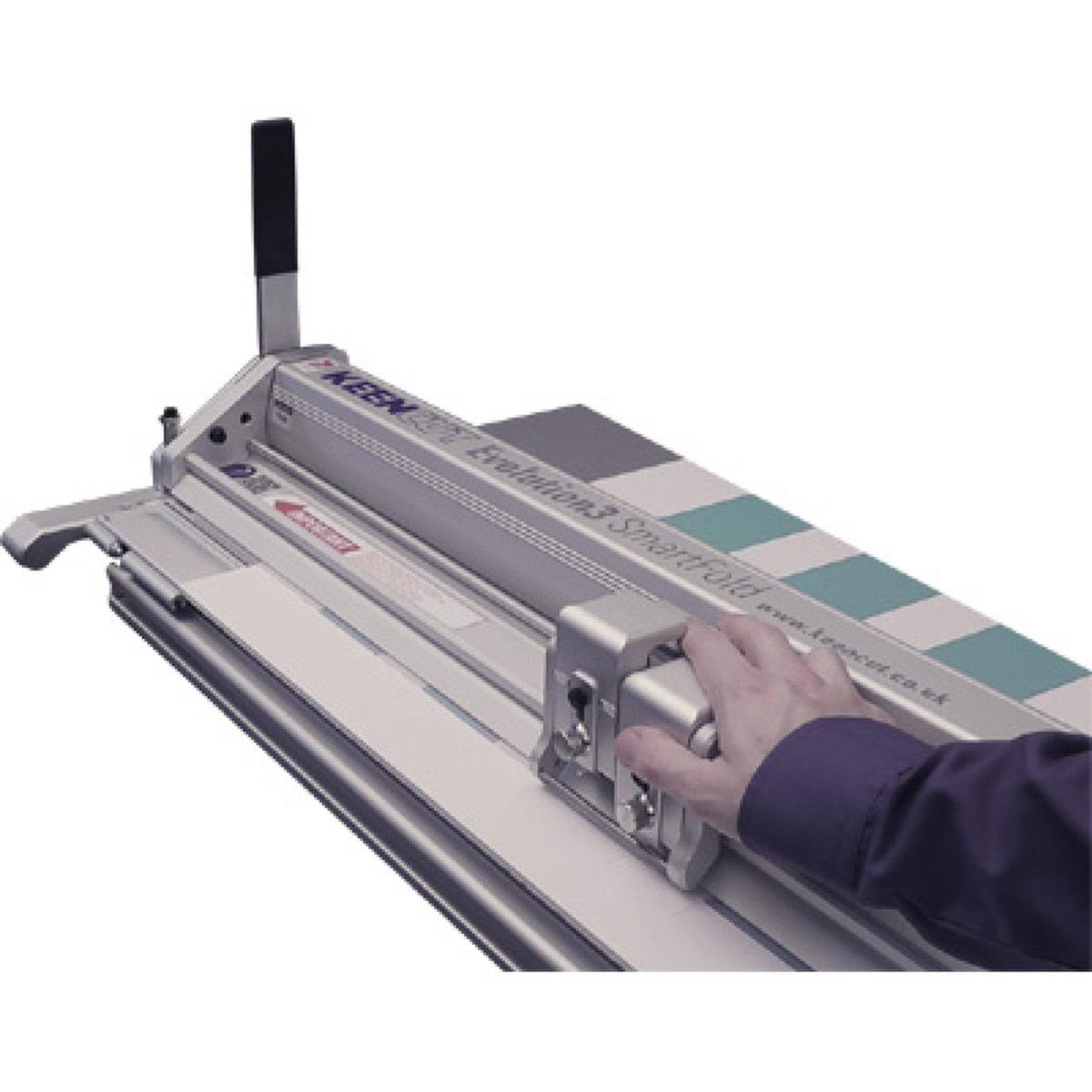

Low Friction Ball Bearings On A Steel Track For Ultra-smooth Operation

• Pre-lubricated ball bearings on steel slide tracks for precision, low friction and years of trouble-free life without adjustment

• 20 year replacement guarantee on all sliding bearings

Future Proof & Easy To Use

• Designed with the future in mind the Keencut SteelTraK enables the selected cutting tools to be fitted and removed in seconds from the unique multi-function counterbalanced sliding carriage with a single finger screw

• All new tool developments fit onto existing SteelTraKs

Telescopic Legs

• Featuring Telescopic legs, the SteelTraK is adjustable for height & minimum fatigue

Perma-lock Squaring

• Precise screw adjusted perma-lock squaring for accurately cut panels every time

Universal 4 Tool Cutting Head With Auto Blade Disengagement

• Blade automatically and safely disengages at the end of cut

Tools Include

• Straightline board cutting for general purpose cutting up to 13mm

• Acrylic scoring for cast Acrylic and Plexiglas up to 6mm

• Glass cutting (when used with optional glass cutting kit) for specialist applications up to 6mm

• Aluminum Composite Cutting (DiBond) up to 4mm

Full Length Extra-grip Clamping System

• Engage simply using the Clamp Handle

• Grips material firming yet pre-printed surfaces are protected by the non-marking silicon rubber grip cords

Transparent Cutline Cursor

• Easy to check where the cut line is using the transparent cursor

• Renewable - fixed - ultra precise - no laser shake - no doubt and no wasted panels

• All tools cut along the same line

Quick Set Production Stops

• Fitted as standard with a pair of left & right Quick Set Production Stops for fast and accurate one-off and production cutting

• For added convenience, additional production stops are available as an optional accessory Twin Wheel Cutting Head - Noiseless & Dust-free

• Heavy duty steel composite twin wheel cutting head. Keencut invention 1983

• Twin Wheels cut DiBond in a single clean pass

SteelTrak Squaring Arm Extension

• Optional Accessory for All Models of SteelTraK

• Extends Left Side of SteelTraK Squaring Arm by 700mm

• Ideal for providing extra support to large boards

• Comes complete with all fixings

Standard Features & Performance

• Integral counterbalance - total convenience - no shock - less fatigue - easy loading

• Extruded back beams - firm support for large & small sheets

• Full length extra grip clamping system

• Heavy duty steel composite twin wheel cutting head. Keencut invention 1983

• Twin Wheels cut DiBond in a single clean pass

• Precise horizontal & vertical scales (Imperial & Metric)

• Wall mounted as standard but with a free-standing option

• Twin Production Stops

• Accepts standard utility blades for the majority of applications

• 3 Standard Turn & Lock ready mounted tools for instant action. Glass cutting can be added for create 4 Turn & Lock Tools.

• Accepts bolt-on accessories; suitable for existing & future innovations

• Precise screw adjusted perma-lock squaring. Accurately cut panels every time

• Rotating Tool Turret for instant tool change

• Transparent cutline cursor - renewable - fixed - ultra precise - no laser shake - no doubt and no wasted panels

• Hinge-out slide track for access and maintenance

• Pre-lubricated ball bearings on steel tracks for precision, low friction & trouble-free life without adjustment

Ease Of Operation & Safety

• Total dust free operation - safe to use near printers and plotters

• Pre-lubricated, low friction ball bearings on a steel track for ultra-smooth operation

• Automatic blade disengagement at the end of cut - blade safely retracts

• All blades cut on the same line. One production stop setting - One measurement - One cutline - No special operator training

• Telescopic legs adjust for height & minimum fatigue

Guarantees & Construction

• 100% manufactured by Keencut Technicians in England

• 99.98% of materials from the best suppliers in Western Europe

• High tensile aerospace aluminum alloy construction

• Super grade anodizing for lifetime good looks and function

• Designed specifically for the design & display industries